The Concept

'Bomb' PC cases are certainly nothing new, but with WMD I hope to take things a step further by designing and building the case from scratch, and adding a few twists to really make the project unique and interesting. Several features of the case are designed specifically with LAN events in mind, though weight probably won't be one of them (can anyone say "cargo trolley"?). I had the idea for building WMD at the end of 2003, right when I was in the middle of another project, which put a dampener on things. I did some sketches and came up with a few themes at the time. The WMD concept was then shelved until May 2004 when I resurrected it and began drawing up plans, concept illustrations, and talking sponsorship with various companies.The plan is to build a custom all-stainless steel case that resembles every fictional hero's worst-nightmare - essentially a 'device' that looks capable of vaporizing a sizable area of the earth's surface. This WMD, however, is designed to take along to LANs more as a Weapon of Mass Gaming Destruction - a high-spec Small Form Factor rig for the best in gaming goodness. I only hope it doesn't clear the venue...(But wouldn't you win by default then? - Ed)

I want the final 'look' of the case to be sleek and clean looking, but with an industrial feel. A few of the general themes I will be following include:

- All stainless steel construction.

- Water-cooled.

- Low noise.

- High performance system components.

- Red LED timer display. Able to count down from the start of a LAN event and continue throughout until the end.

- Keylock switches, Keypad control, red flashing indicators.

- A high quality build, utilising some laser-cut pieces, and CNC machined timer bezel.

- Easily upgradable/accessable.

- Tough, shock-absorbing construction, able to take a knock.

- Plus a lot more that will become clear over the course of the project.

The System

The system will be based around a Shuttle Socket 939 Small Form Factor Motherboard (from a Shuttle SN95G5), paired with AMD's killer Athlon 64 FX55 CPU. I'm aiming for the performance of this mod to match it's looks!The final system will include:

- Shuttle SN95G5 Socket939 SFF Motherboard.

- AMD Athlon64 FX55 CPU.

- 2GB of Corsair TWINX 2048-3200C2 XMS3200 memory.

- 2 x 74GB Western Digital Raptor 10k RPM Hard Disk Drives.

- Sapphire X800XT PE Graphics Card.

- Creative Audigy 2ZS Sound Card.

- Panasonic UJ825 Slimline Slot-Loading DVD-RW (from KustomPCs).

- 2 x Engelking U1-6250C Fanless SFF PSU's (to be watercooled).

- Custom-built Radiator, specifically for this project, from HWLabs (makers of the famous Black Ice Series Radiators).

- All innovatek Water Cooling from innovatek and CoolercasesUK, including 2 HPPS 12v Pumps.

- Shuttle PN15 Wireless LAN Module.

- Shuttle PN31 Remote Control (integrated into the case).

- Switchbays and HDD Silencers (amongst other goodies) thanks to KustomPCs and MNPCTECH.

Also part of the system, and set for some serious modding...

- a Shuttle XP17 Flat Panel Display.

The Planning

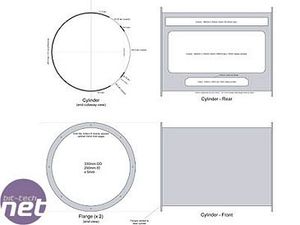

I used mainly Adobe Illustrator to draw up the plans for the case. I've yet to learn to use CAD-type software (maybe next project), but considering my last project was scribbled out in a sketchbook, properly illustrated drawings were a step up for me! One good aspect of IllustratorCS is the facility to be able to save 2D drawings as .DXF / .DWG CAD files - a big help when dealing with laser-cutting. I got very detailed with measurements, as is important in any SFF project, where you are trying to pack a lot into as small a space as possible.Fortunately, the luxury of custom-building a case is you simply make it big enough to be able to fit everything you want to put in it! But how big to make it is where careful planning comes in. I'd like to add a line to the modders mantra of 'measure twice, cut once' - 'Plan three times...measure twice, cut once'...

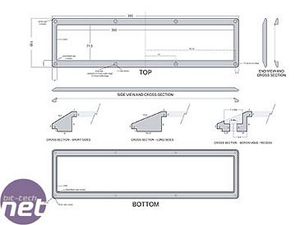

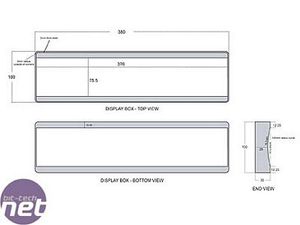

The Timer consists of two parts - the bezel and the box-like housing. As the bezel was going to be CNC milled, it needed to have exact dimensions worked out for every part of it (you can see various cross-sectional measurements even). The box had to sit flush to the curve of the main cylinder, so needed a curve in the sides to match the radius of the curve of the case. Both these parts were derived from the measurements of the actual display electronics that will be fitting inside them. In a way the whole case kind of flowed from the timer, as I had bought the timer first and based a lot of the look and dimensions of the mod on it.

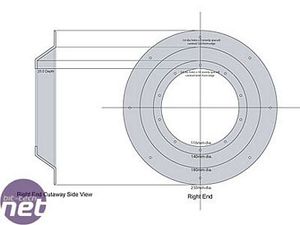

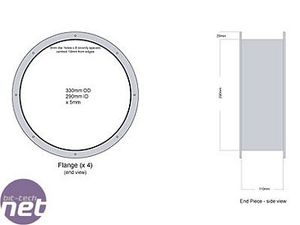

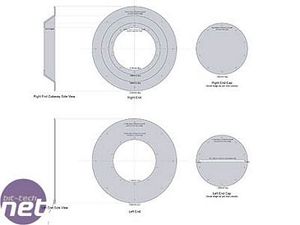

The air intake and the plan for the end sections. These were fairly simple to plan, though the main concern, with having several bolt-on pieces, was ensuring all the holes lined up. It was a situation of the inner holes on one piece having to line up with the outer holes on the next piece, and so on.

The plan for the Main Cylinder was the trickiest. I had to re-discover some maths I hadn't used in a long time to endlessly work out arc lengths from chord lengths and so on - you can see the result in the top right of the cylinder plan, where I did a cutaway diagram with all the arc measurements included. My brain hurt after a while, but I stuck at it, as the position of the openings and their dimensions were critical. The drawings for the end covers were fairly straightforward by comparison.

After I'd planned everything, I dropped off a couple of drawings to the laser cutters (who also have a large CNC router setup) for cutting the various sheets and flanges, plus the milling of the display bezel.

With the planning done, it was time to take a break for a couple of weeks while I waited on my cutting/milling and concentrated on sorting system components, fasteners and a million-and-one other things I needed for the project.

With all that done, it was time to go build something...

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.